Software & Analytics

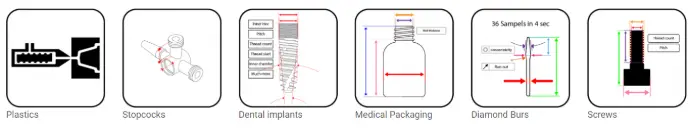

Quality Management Software SPC - Active Shop

- Sophisticated Real Time Data Collection

- Advanced Charting Variable & Attribute (30 charts, Pre-control XbarR, Histogram, Normality & more)

- Both Offline and Online modules available

- Powerful Report generation for Management

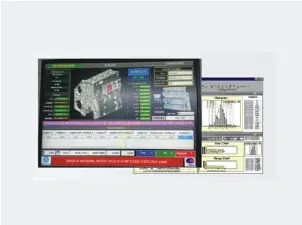

BATTERY DIGITAL-TWIN & BOXY-LINK CLOUD

- Real time multi machine Monitoring

- Downloadable PDF Reports

- Set up SMS and E-Mail alerts

- Downloadable raw data in CSV

- APIs for 3rd Party software integration

- Cloud and locally deployable software

Computer Vision Jv200

Group Highlight

Ring Illumination ,Back Light panel, Large FOV

Main Markets

Cables, Profiles, Castings, Plastic parts, Automotive, optical lens.

MV360

Group Highlight

360-degree scanning with Motorized Theta and Z STAGE for long parts. Collimated Backlight Illumination.

Main Markets

Implant, Stopcocks, Stents, medical, Cylindrical parts measurement.

Software

All-In-One Vision applications software

MAD vision software has a rich image processing library for metrology application, defect , sorting, matching etc.

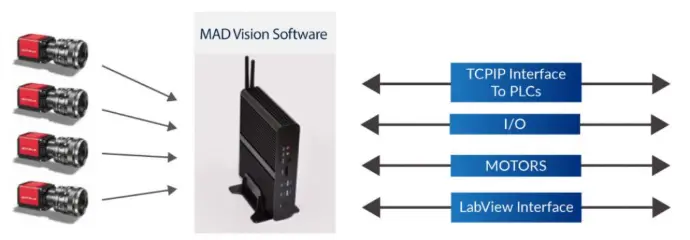

Can be interfaced to LabView and C# for easy enhance the connectivity to other applications with a very cost effective way.

MAD vision software will also provide you the ability to control servo motors and I/O units for complete machine vision applications.

- Critical dimensions measurement

- Data collection for SPC analysis report.

- Integration to costumer production floor.

- Application tailoring for the customer needs.

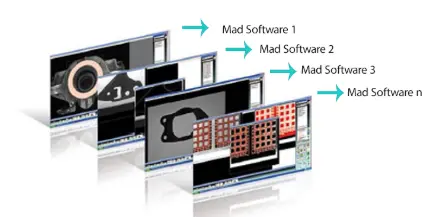

The MAD vision software can be used as a platform to construct a wide range of applications, from simple single camera stations to a complete multi-camera station, all in one solution.

MAD Vision Software

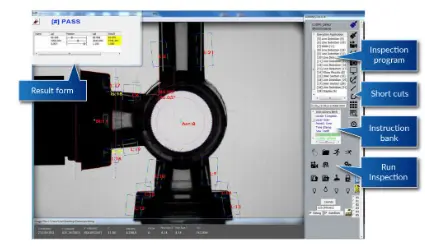

User Interface

vA simple interface is used to construct applications. Our customers say

“it’s the world’s simplest interface for constructing vision applications”

MAD Vision Software

Data sharing and SPC

The MAD vision software uses a smart result interface, enabling you to add result manipulation,

mathematical calculation with a built-in pass/fail mechanism.

MAD vision software can forward the results according to any and all of the following options:

- Informative popup dialog on the user screen

- Excel templates and csv files for SPC analysis

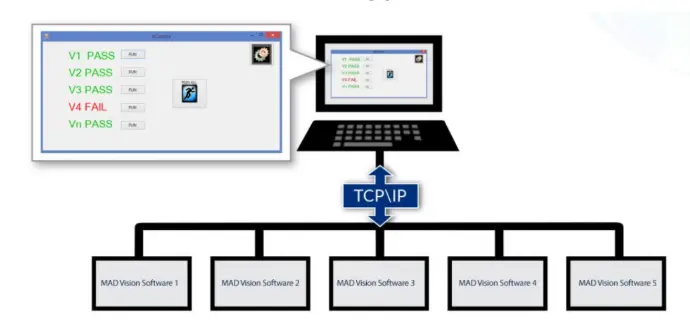

- PLC or other computer using TCP\IP protocol

- LabView application

- .NET – Build and customize you own user interface

Connectivity

- The MAD vision software is fully integrated with third-party motion controller, I/O unit, 3D sensors and much more!

- Send and Receive control messages with other devices through serial port and TCP/IP sockets

- Using TCP\IP, the MAD vision software can be controlled by PLCs

MAD Vision Software

MAD Vision Software

Summary

- With MAD vision software you don’t need any prior programming knowledge for application setup

- MAD vision software has an Intuitive user interface

- MAD vision software has a large and powerful image processing library

- MAD vision software can process multiple cameras with different vision tasks at the same time

- MAD vision software has an easy integration with Excel for a SPC analysis

- MAD vision software can interface remotely to C#, LabView and PLC’s

- MAD vision software can communicate with motion controllers and I/O units

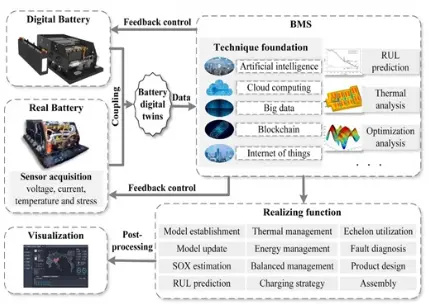

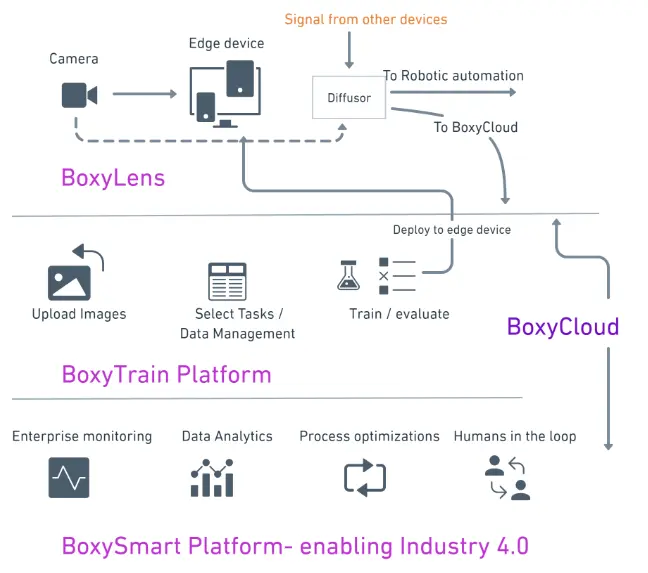

Boxy link AI Enabled Machine Vision Software

Build cloud hosted, on premise or completely isoloated on-device solutions

Highly flexible topology for different buisness needs. Data isolation and data protection of your valuable data is ensured

Out-of-the-box pre-trained models for most industrial components

Reduce the data need for getting the most accurate model and train on multiple architecture

Central deployment of AI models and data processing for industry 4.0 compliance

Capture and improve the productivity of production pipeline with the data of quality inspection in indstry 4.0 compliance format

Low code OR completely managed AI and measurement solutions

Get the feasibility study or test the quality of the model yourself with boxylink platform

A hybrid solution with Vision AI and inspection sytems

Build automation from the output of the vision inspection system to further improve the productivity of your production line